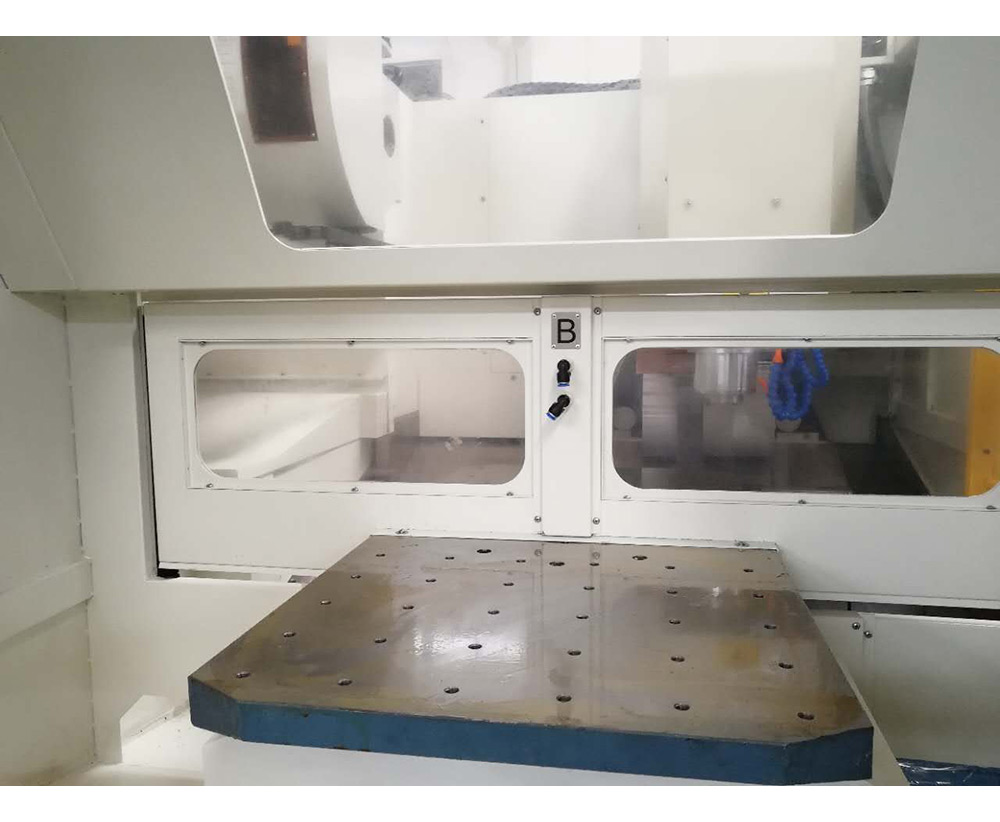

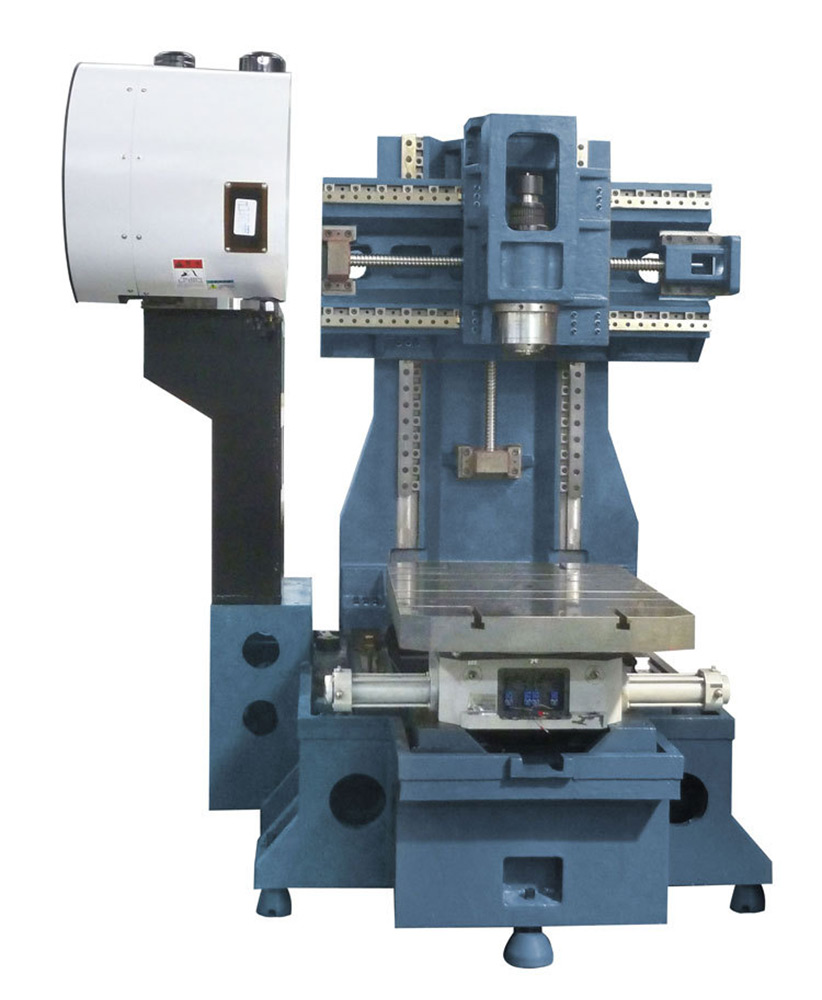

V-600S Twin Pallet CNC Vertical Milling Center

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video:

QUICK OVERVIEW

V-600S is a CNC vertical machining center for milling, tapping, boring, reaming etc of metallic material parts. Machine frame adopts of moving column and moving beam, rotary worktable structure. 3 axis make constant mass linear motion, which are irrelevant to workpiece weight. So wearing of 3 axes transmission parts are small in long term use and precision stability is very good. Three axes are equipped with high precision high speed linear guide made in Taiwan (Hiwin or PMI). Large diameter ballscrews ensures precision and stable positioning motion. Pallet changer saves workpiece clamping and unclamping time. Column moves longitudinally on base as Y axis. Beam moves up and down on column as Z axis. Headstock moves horizontally on beam as X axis.

Contact us

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video:

QUICK OVERVIEW

V-600S is a CNC vertical machining center for milling, tapping, boring, reaming etc of metallic material parts. Machine frame adopts of moving column and moving beam, rotary worktable structure. 3 axis make constant mass linear motion, which are irrelevant to workpiece weight. So wearing of 3 axes transmission parts are small in long term use and precision stability is very good. Three axes are equipped with high precision high speed linear guide made in Taiwan (Hiwin or PMI). Large diameter ballscrews ensures precision and stable positioning motion. Pallet changer saves workpiece clamping and unclamping time. Column moves longitudinally on base as Y axis. Beam moves up and down on column as Z axis. Headstock moves horizontally on beam as X axis.

Contact us

| ITEM | V-600S | |

| Worktable | Table type | Twin pallet changer |

| Table size/(L*W) | 1000x600 | |

| T-slot size/mm | 3x18x140 | |

| Max load on the table/kg | 250 kg | |

| Travel | Max. X/Y/Z axis travel | 600/400/350 |

| Spindle nose to table surface/mm | 120-475 | |

| Spindle nose to column surface/mm | 450 | |

| Spindle | Spindle taper | BT30 |

| Max. Spindle speed/rpm (Standard) | 12000 rpm | |

| Spindle driven (Standard) | Direct drive | |

| Tool unclamp | Mechanical Type | |

| Feeding | Max cutting feed rate(MM/min) | 1-10000(mm/min) |

| X,Y,Z rapid traverse | 48/48/48m/min | |

| A.T.C | Tool magazine type | Hat Type |

| Tool Magazine capacity | 16 | |

| Max. tool diameter and length | Ø 120x200 | |

| Max. tool weight | 3 kg | |

| Tool shank type | BT30 | |

| Servo Motor | Spindle motor | 3.75/5.5kW |

| X/Y/Z axis servo motor (Mitsubishi) | 1.5/1.5/2.2 kW | |

| Coolant motor | 0.49 kW | |

| General | Air Requirements | 6KG |

| Power Capacity | 10KVA | |

| Measurement | 2.6x2.0x1.9m | |

| N.W. | 4T | |

| Standard configuration | Optional configuration | |

| FANUC/Mitsubishi control | GSK control | |

| Heat exchanger for electric cabinet | Rotary table (fourth, fifth axis) | |

| Standard RS-232 interface & RS-232 cable | Chip conveyor and chip bucket | |

| Hydraulic system | Spindle oil chiller | |

| Arm type A.T.C. 24 tools | Oil mist filter | |

| Fully enclosed enclosure | Automatic voltage regulator | |

| Automatic centralized lubrication system | Spindle speed 15000rpm | |

| Spindle rigid tapping | Spindle speed 20000rpm | |

| Remote MPG | ||

| Working light | ||

| Working status indicating light | ||

| 3 phase isolate transformer | ||

| Toolkits | ||

| Leveling screws and pads | ||

| Operations manual | ||

| Z axis Nitrogen cylinder |