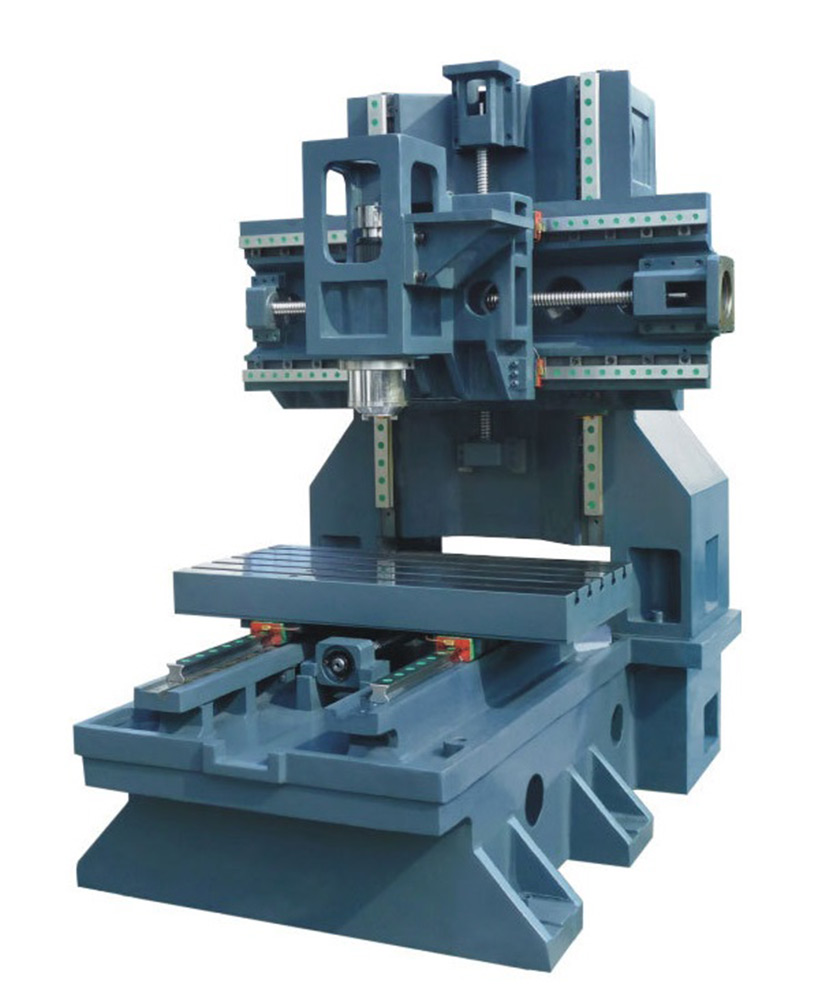

1270D Heavy Duty CNC Vertical Milling Machine Center

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video:

QUICK OVERVIEW

V-D series traveling beam type vertical CNC milling machine center is middle size range of vertical CNC milling machine center with high speed and high rigidity. It is a new generation of JASU VMC products owning national patent. The models have full processing function of milling, boring, drilling, tapping and reaming etc. It can be equipped with full enclosed-loop linear scales, coolant through spindle, 4 axes simultaneous motion etc. It is exactly suitable to the application in various industries, like machinery, automobile, mould, aerospace, motor and valves etc.

Contact us

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video:

QUICK OVERVIEW

V-D series traveling beam type vertical CNC milling machine center is middle size range of vertical CNC milling machine center with high speed and high rigidity. It is a new generation of JASU VMC products owning national patent. The models have full processing function of milling, boring, drilling, tapping and reaming etc. It can be equipped with full enclosed-loop linear scales, coolant through spindle, 4 axes simultaneous motion etc. It is exactly suitable to the application in various industries, like machinery, automobile, mould, aerospace, motor and valves etc.

Contact us

| Specification | V-850D | V-1060D | V-1270D |

| Worktable | |||

| Table size | 1050 x 500 mm | 1300 x 600 mm | 1400 x 700 mm |

| T slot size (width * gap) | 18 x 90 mm (5 pcs) | 18 x 100 mm (5 pcs) | 22 x 120 mm (5 pcs) |

| Max. load capacity | 1000 kg | 1000 kg | 1500 kg |

| Travel | |||

| Max. XYZ axis travel | 800/500/500 mm | 1000/600/600 mm | 1200/700/700 mm |

| Spindle nose to worktable | 150-650 mm | 150-750 mm | 150-850 mm |

| Spindle center to column surface | 550 mm | 650 mm | 750 mm |

| Spindle | |||

| Spindle taper | BT40 | BT40 | BT40 |

| Max. spindle speed | 8000 rpm | 8000 rpm | 8000 rpm |

| Spindle drive | Belt drive | Belt drive | Belt drive |

| Feeding | |||

| XYZ axis cutting feedrate | 1-10 m/min | 1-10 m/min | 1-10 m/min |

| XYZ axis rapid traverse | 30/30/30 m/min | 30/30/30 m/min | 30/30/30 m/min |

| XYZ axis ballscrew size | ∅40-P10 | XY:∅40-P10 Z:∅50-P10 | XY:∅40-P10 Z:∅50-P10 |

| Positioning accuracy (JIS) | ±0.003/300 mm | ±0.003/300 mm | ±0.003/300 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.003 mm |

| A.T.C. | |||

| Tool magazine type | Arm type | Arm type | Arm type |

| Tool capacity | 24 pcs | 24 pcs | 24 pcs |

| Max. tool dia. x length | 80 x 200 mm | 80 x 200 mm | 80 x 200 mm |

| Max. tool weight | 7 kg | 7 kg | 7 kg |

| Tool change time (T-T) | 2.8 s | 2.8 s | 2.8 s |

| Servo motor | |||

| Spindle motor (kw) | 7.5/11 | 11/15 | 11/15 |

| XYZ axis servo motor (Fanuc) | 1.8/1.8/1.8 kw | 3.0/3.0/3.0 kw | 3.0/3.0/3.0 kw |

| Coolant motor(kg) | 0.49 | 0.49 | 0.49 |

| General items | |||

| Air required (kg) | 8 | 8 | 8 |

| Power capacity (KVA) | 20 | 20 | 30 |

| Dimensions (M) | 2.7 x 2.25 x 2.5 | 3.2 x 2.26 x 2.9 | 3.4 x 2.6 x 3.0 |

| Net weight (T) | 7.5 | 9 | 1.05 |

| Standard Configuration | ||

| No. | Standard accesories | Qty |

| 1 | FANUC CNC system package 0i-MF(5), including Beta series servo motors and servo drive | 1 set |

| 2 | Standard RS-232 interface & communication cable, USB, CF card interface | 1 unit |

| 3 | Spindle rigid tapping | 1 unit |

| 4 | Arm type ATC T24 | 1 set |

| 5 | Tool pressure cylinder | 1 pcs |

| 6 | Pneumatic system | 1 unit |

| 7 | Fully enclosed cover | 1 set |

| 8 | Coolant system | 1 set |

| 9 | Auto centralized lubrication system | 1 set |

| 10 | Working light, working signal light | 2 pcs |

| 11 | Heat exchanger of electrical cabinet | 1 pcs |

| 12 | 3 Phase isolated transformer | 1 set |

| 13 | Spindle air blow, coolant gun, air gun, auto safety door | |

| 14 | Toolkit for setup | 1 set |

| 15 | Leveling screws and blocks | 1 set |

| 16 | English operation maintenance manual, Fanuc manual (CD), Electrical manual | 1 set |

| Optional Configuration | ||

| No. | Optional accessories | Remarks |

| 1 | Siemens CNC sytem 828D | same price with Fanuc 0i-MF5 |

| 2 | Mitsubishi CNC system M80B | same price with Fanuc 0i-MF5 |

| 3 | 4th axis function of CNC system (without motor, drive and hardware) | |

| 4 | Belt spindle 10000rpm | |

| 5 | Direct spindle 10000rpm | |

| 6 | Direct spindle 12000rpm (7.5/11KW) | |

| 7 | Motor spindle 15000rpm | |

| 8 | BT50 spindle max.6000rpm | |

| 9 | Spindle oil chiller | |

| 10 | Oil mist filter | |

| 11 | CNC rotary table (Available size 210, 255) | |

| 12 | Manual or automatic tailstock (Applied with rotary table) | |

| 13 | Tilting rotary table | 5 axis with 4 axis simultaneous control |

| 13 | Coolant through spindle 30 Bar | Only for belt spindle and motor spindle |

| 14 | Chain type chip conveyor & chip cart | |

| 15 | Oil skimmer | |

| 16 | Renishw tool setter | |

| 17 | Renishaw part probe | |

| 18 | Overseas 2 years warranty for CNC system (For Fanuc and Mitsubishi) | No free guarantee from CNC system supplier for the exported CNC machine |